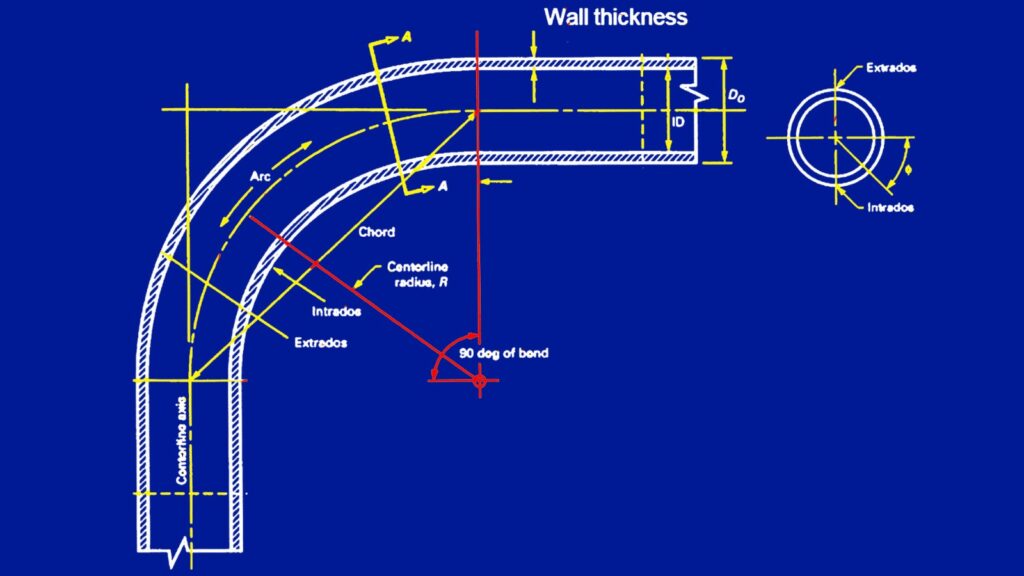

Induction bends form an important link in the pipeline chain of delivery that requires careful planning and consideration to SAFETY, and to deliver high value and high benefit to cost ratio solutions to pipeline routing problems. It is a dynamic process aims to achieve the consistent desired values agreed by both parties on the geometrical dimension & mechanical properties after bending.

ASME B16.49 and other references ISO 15590-1, DNV OS F101 list specific codes, procedures, and guidelines for the testing on Tensile, Yield, Toughness, and the acceptable dimensional tolerances after bending

TechnoBend’s four computerized operated production lines are capable of bending of diameters up to 56” with high degree of flexibility on bend radius, angle, and plane.

The bending process requires advance control over the principal manufacturing parameters of temperature, speed and cooling rate, as well as the important start and stop procedures, in order to achieve consistent and acceptable results

Each project represents a unique set of circumstances which must be defined that requires to develop a suitable Manufacture Procedure Specification (MPS), & Inspection Test Plan (ITP)

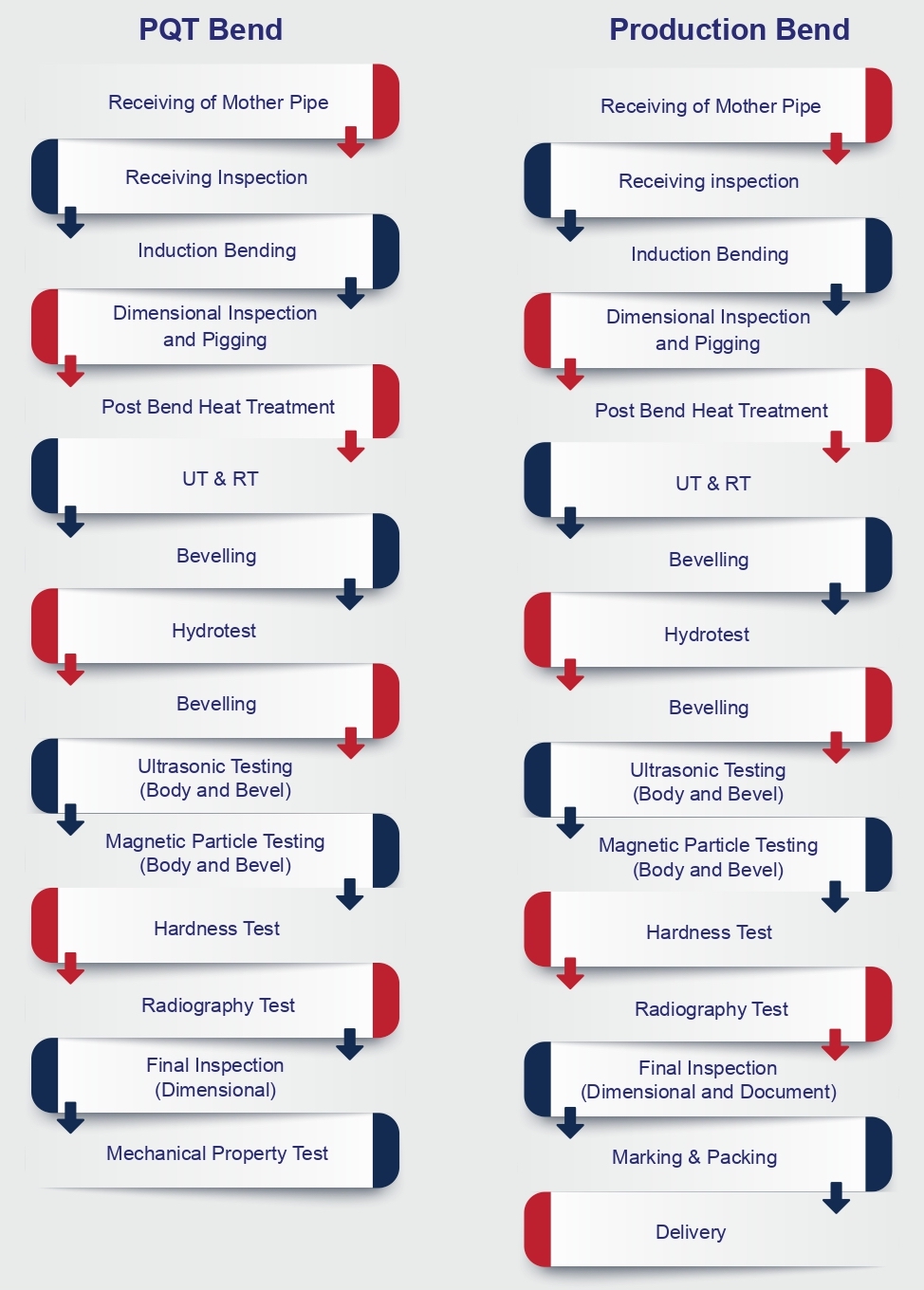

Physical properties of induction bends can be demonstrated through the manufacture of Prequalification Test Bend (PQT) and subsequent mechanical testing. Once qualified, these parameters shall be set as the target parameters for all subsequent production bends as “clones”