Non destructive testing determines the existence of flaws, discontinuities, leaks, contamination, thermal anomalies, or imperfections in materials, components or assemblies without impairing the integrity or function of the inspected component. It is also utilized for real-time monitoring during manufacturing, measurement of physical properties such as hardness and internal stress, tolerances, & alignment.

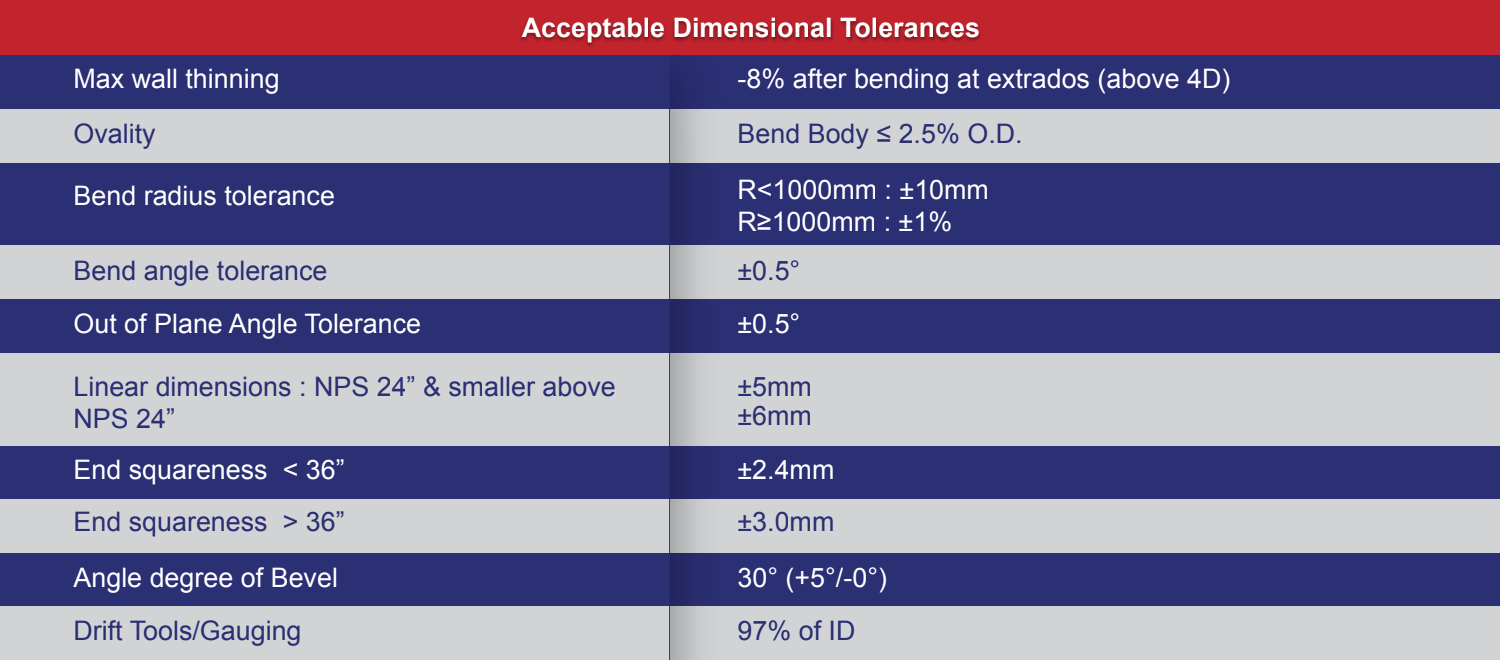

Bend Dimensional Tolerances

The bend angle, center-to-face dimensions, bend radius, chord lengths, squareness, and bend plane shall be measured and recorded for each bend.

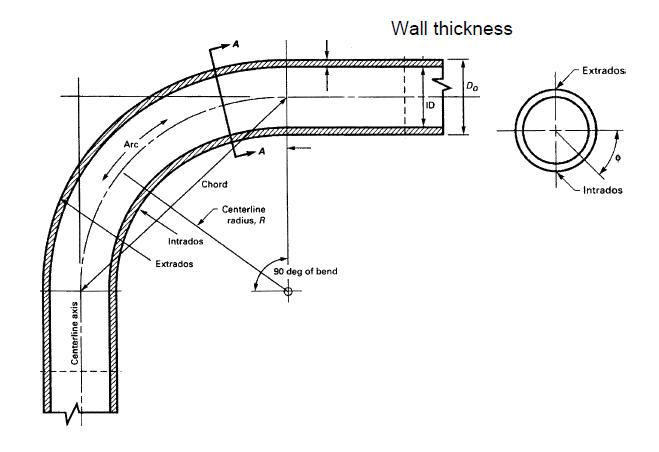

Bend Dimensional Terms

Tangent Point/Transition area

The completed bends shall be free of cracks, bumps, wrinkles, notches, silvers, sharp projections, scabs, gouges, and/or other defects.

Ultrasonic Testing (UT):

high frequency sound energy used to determine the structural integrity of a material. The use of various modes of sound can provide vital information related to a material. Transmitted or reflected ultrasonic energy is displayed on a test unit and evaluated

Radiographic Testing (RT):

RT involves using penetrating gamma- or X-radiation on materials and products to look for defects or examine internal or hidden features. Is a short wave-length electromagnetic ionizing radiation energy used to penetrate materials and provide an image for evaluation. Variations in the image are caused by changes in the structure due to attenuation or absorption. RT can be performed using either a gamma or X-ray source.

Magnetic Particle Testing (MT):

the use of magnetic lines of flux to determine discontinuities in the surface (or near surface) of a test object. This NDT method is accomplished by inducing a magnetic field in a ferromagnetic material and then dusting the surface with iron particles (either dry or suspended in liquid). Fine magnetic particles are attracted to leakage fields and indications are formed that can be seen visually.