Destructive Examination

Destructive testing of specimen for prequalification at the laboratory is designed to produce consistent & repeatable result as representative of others that are manufactured with similar process will produce similar results.

The objective is to ensure that our products will perform safely under extreme stress, high temperature, & extreme conditions.

Once qualified & approved, these parameters must be set as the target parameters for all

subsequent production bends. The production motherpipe would be prepared and inspected

and then induction bent as “clones” of the approved procedure. The completed bends

would be machined with bevel ends, tested and inspected, coated as specified and labeled.

Documentation would be assembled into a consolidated manufacture data report detailing all aspects of manufacture, testing, and inspections.

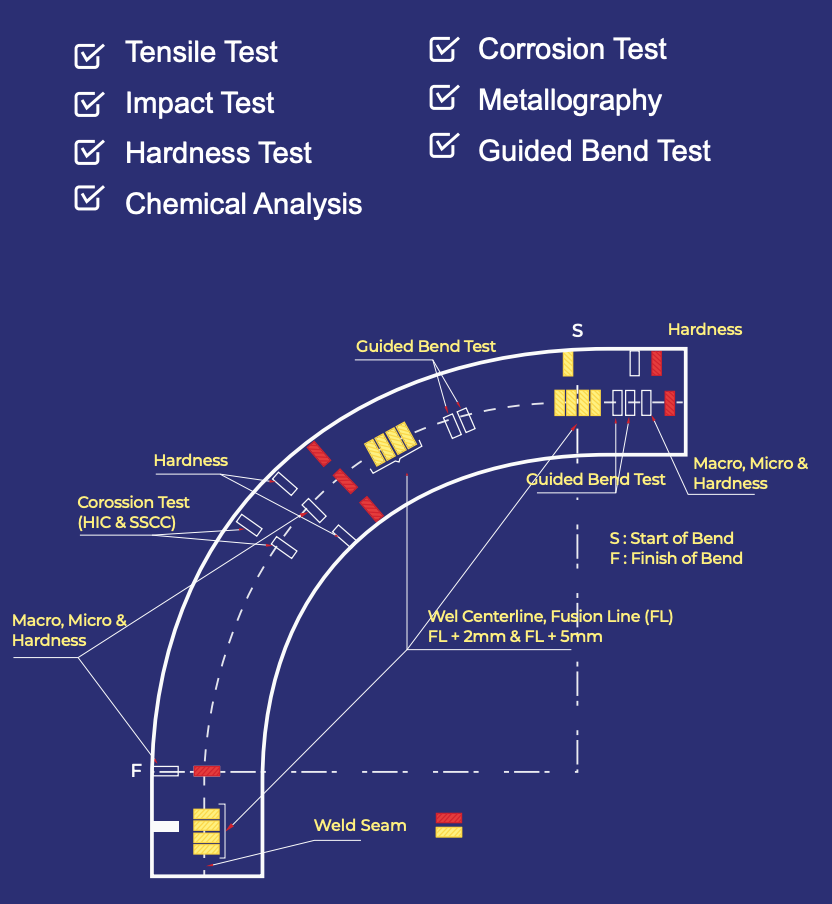

Location of Speciment